Deprecated: Function create_function() is deprecated in /var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line 4280

Deprecated: Function create_function() is deprecated in /var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line 4368

Deprecated: Function create_function() is deprecated in /var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line 4379

Ultimate

The first ALUMAX-ULTIMATE was installed in Turkey in 2007 and had a diameter of 24 m. Beginning from then ATECO has been supplying many ALUMAX-ULTIMATE in a various diameters from 3 meters to 100 meters.

Cost effective and easy to install system, which could be used in new or old tanks. Each ALUMAX-ULTIMATE is in accordance with your requirements.

Saves up to 99% of product evaporation. Product savings depend on the stored product, the diameter of the tank and the total turnover per year.

When was the first ALUMAX-ULTIMATE made?

The first ALUMAX-ULTIMATE was installed in Turkey in 2007 and had a diameter of 24 m. Beginning from then ATECO has been supplying many ALUMAX-ULTIMATE in a various diameters from 3 meters to 100 meters.

What does the ALUMAX-ULTIMATE cost?

ALUMAX-ULTIMATE is a cost effective and easy to install system, which could be used in new or old tanks. Each ALUMAX-ULTIMATE is in accordance with your requirements. You will be pleased to see how economic environmental protection could be.

How efficient is the ALUMAX-ULTIMATE?

ALUMAX-ULTIMATE saves up to 99% of product evaporation. Product savings depend on the stored product, the diameter of the tank and the total turnover per year.

What is the estimated pay-back period of ALUMAX-ULTIMATE?

This depends on value and volatility of the stored product. This could be 16 months for refined products.

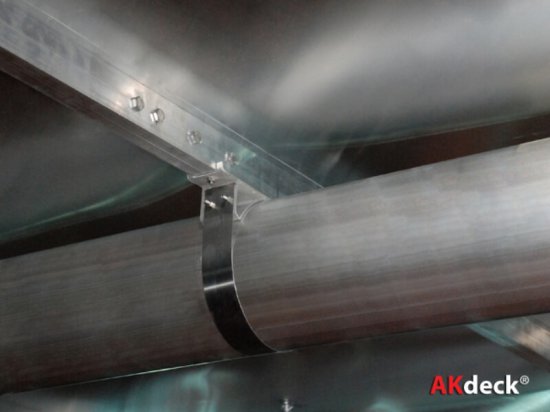

Why are there legs fitted to the underside of the ALUMAX-ULTIMATE and are they permanently in position?

These legs are fitted to let the tank operators to gain access to the tank bottom when the ALUMAX-ULTIMATE is lowered. These legs are permanently fitted, they go up and down with the ATECODECK and are usually located such the ALUMAX-ULTIMATE could be lowered to rest on the tank floor, just above the tank shell manhole. These legs are available in an adjustable version, so the operator could determine the minimum height of the ALUMAX-ULTIMATE himself.

Can internal tank maintenance work be carried out with the ALUMAX-ULTIMATE installed?

Certainly! ALUMAX-ULTIMATE is lowered onto its legs and if burning work is to be carried out, properly protected, then most maintenance work could be carried out from the top of the ALUMAX-ULTIMATE. If heavy equipment has to be located on ALUMAX-ULTIMATE then the load should be distributed over as many of the legs as practical using scaffold boards.

Is ATECODECK compatible to all products?

ALUMAX-ULTIMATE is made from aluminium, which is perfectly compatible with most stored products. Besides, we could supply all stainless steel or a combination of aluminium and steel materials to suit any requirement.

Is the seal between the tank shell plates and the ALUMAX-ULTIMATE advisable for all types of stored product?

Before the preparation of our proposal for ALUMAX-ULTIMATE we should know the stored product so that we could ensure all the material used to manufacture the ALUMAX-ULTIMATE including the seal is compatible with the stored product. If in later stages the tank is used to store a different product we recommend that the operator contact ATECO with details of the new product and we will advise if any modifications are required to the ALUMAX-ULTIMATE or the seal.

Is there a minimum or maximum diameter of tank which could be fitted with a ALUMAX-ULTIMATE?

There is not any limitation on the maximum diameter of tank which could be fitted with ALUMAX-ULTIMATE. Depending upon the stored product (low SG) there could be some difficulties to overcome the buoyancy for the ALUMAX-ULTIMATE if the tank diameter is less than 3,000 mm.

Why does ALUMAX-ULTIMATE use 8“ floaters and not 10“ like some competitors do?

The advantage of using the smaller diameter of floatation tube is that the ALUMAX-ULTIMATE takes up less space in the tank and therefore maximizes the volume of the stored product. Also the vapor space under the ALUMAX-ULTIMATE is smaller than with larger diameter floaters.

[rtbs name=”ultimate”]