We help the world growing since 2004

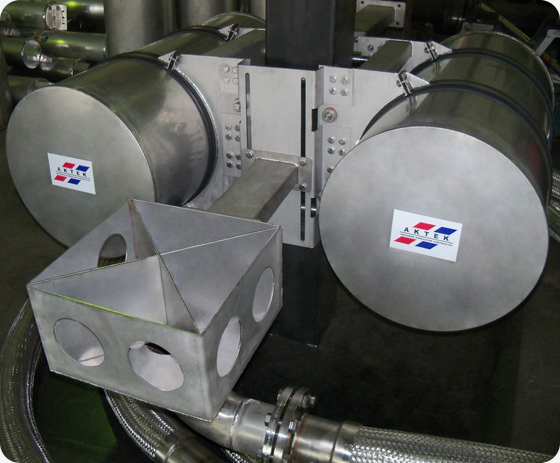

Floated Oil Skimmer

- Home

- Floated Oil Skimmer

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4280

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4368

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4379Applications

ATECO Skimmer systems are a proven solution for draining a light liquid product off the top of a heavier product in a cone or dome roof storage tank. The Skimmer floats on the top product (ex. oil over water) to collect the lighter of two non-mixable liquids into a vortex breaker. The liquid is then drained out of the tank through ATECO’s Resist-All-Clad flexible pipe. Skimmers are made of stainless steel to perform in the most corrosive product environments. An intake fitting and vortex breaker ensure optimal flow as the fluid starts into the skimmer conduit. The Skimmer intake is adjustable to control the amount of liquid that is collected.

ATECO stainless steel flexible pipe features 100% aromatic resistance and includes a smooth internal fluidway for maximum liquid flow. Draining the light fluid is controlled by using a valve at the shell nozzle. Pumps can also be used to draw the light fluid out of the tank. Other ATECO hose assemblies and carbon steel Skimmer components are available on request.

| [rtbs name=”floated-oil-skimmer”] |

|

|---|

: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

34

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4331

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4368

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4379

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

66

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

34

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4331

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4368

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4379

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

66

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

34

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4331

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4368

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4379

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

66

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

34

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4331

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4368

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4379

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

66