We help the world growing since 2004

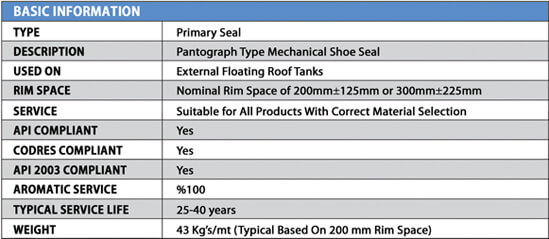

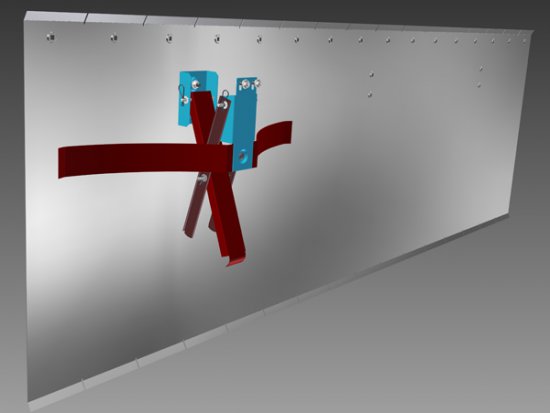

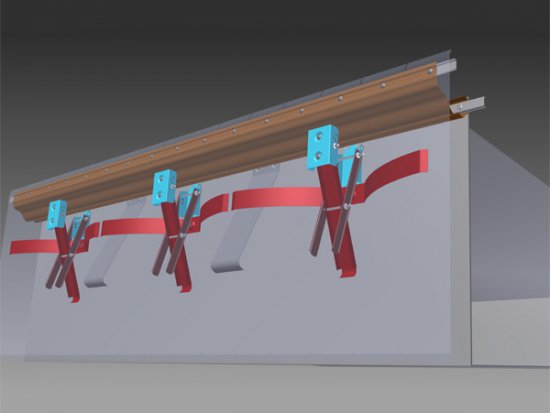

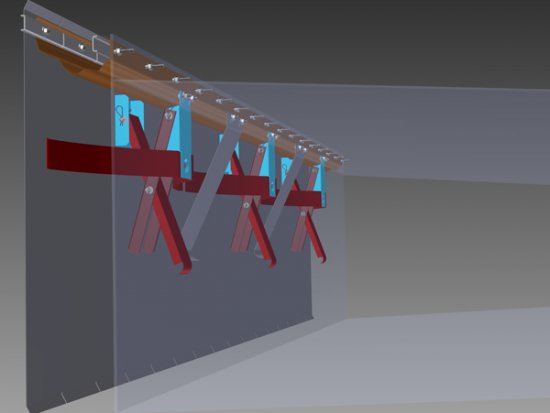

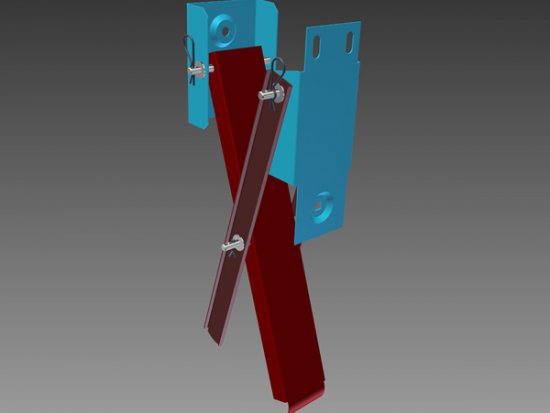

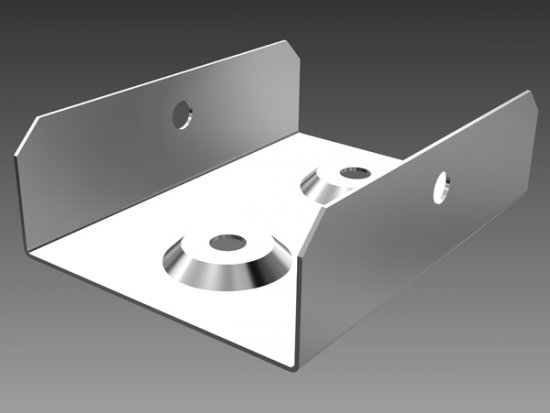

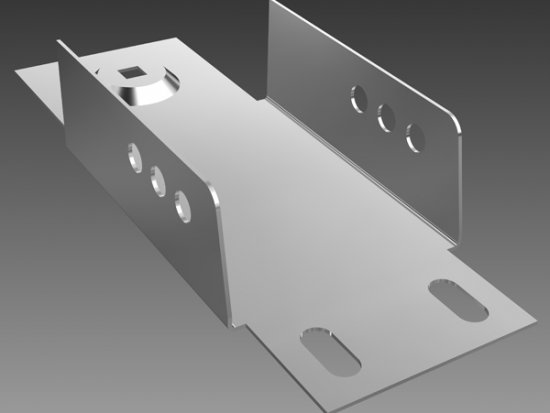

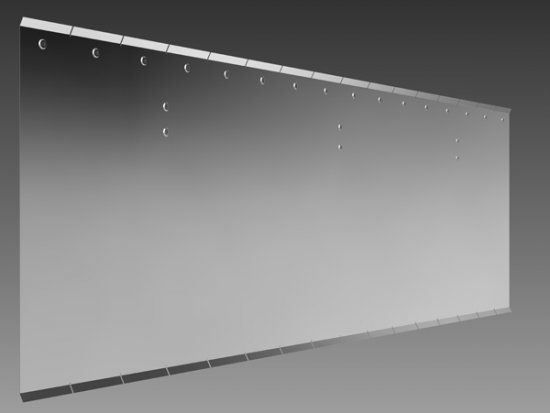

Primary Seal – Pantograph Type

- Home

- Primary Seal – Pantograph Type

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4280

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4368

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4379Primary Seal – Pantograph Type

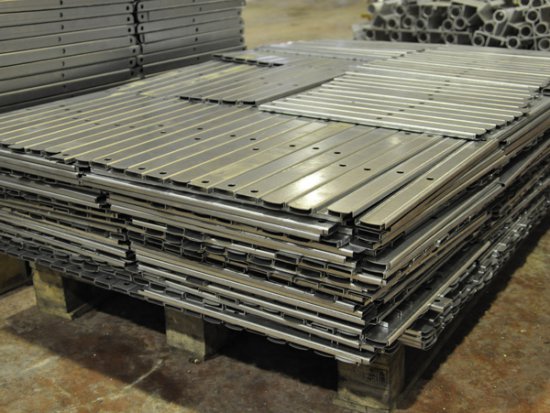

Variations

Several variations on this basic seal type exist including one to service riveted tanks.

Wax Scraper Plates

These can be provided to deal with waxy crude deposits on tank shells.

Regulatory Compliance

ATECO Tank Engineering seals meet or exceed the allowable gap requirements set forth by the governmental and regulatory agencies throughout the universe. This design will show superior sealing ability throughout the roof travel; accounting for roof shifting, out of roundness, buckling, and the expansion and contraction requirement of each tank.

Guarantee

ATECO TANK warrants its seals to be free from defects in the material and workmanship for a period of two year. Our liability under any express or implied warranty is limited to the purchaser price of any part found defective. Any seal systems installed by ATECO TANK TECHNOLOGY ENGINEERING SERVICE will have an additional two-year warranty.

| [rtbs name=”primary-seal-pantograph-type”] |

|

|---|

: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

34

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4331

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4368

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4379

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

66

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

34

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4331

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4368

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4379

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

66

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

34

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4331

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4368

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4379

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

66

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

34

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4331

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4368

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4379

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

66