We help the world growing since 2004

Graver Foam Seal

- Home

- Graver Foam Seal

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4280

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4368

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

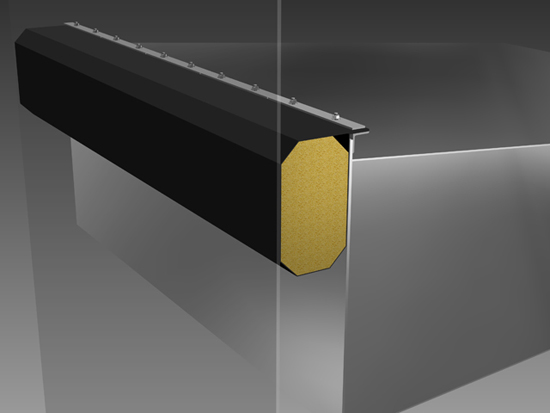

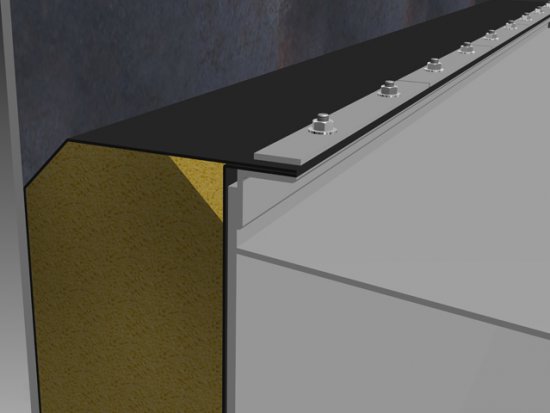

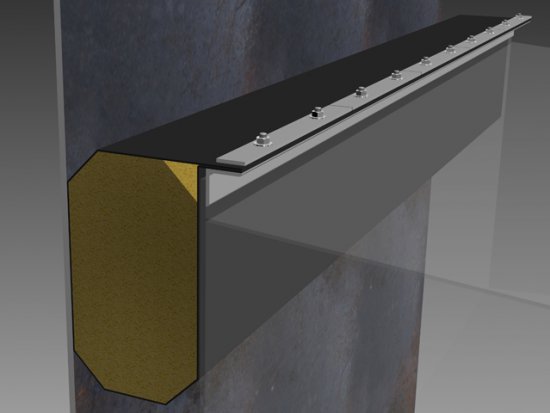

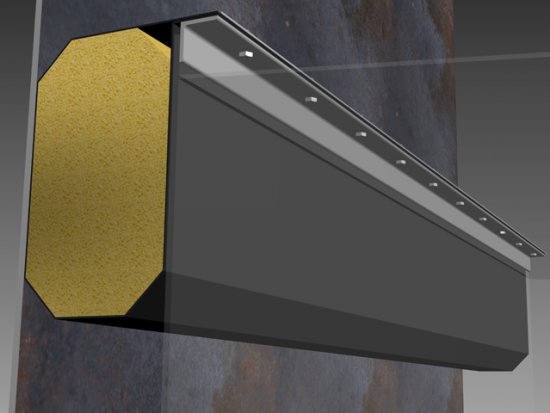

4379ATS-FS5 Foam Seal – The flexible foam filled primary rim seal consists of a series of foam blocks which are covered by an envelope and held down by steel plates. The foam blocks compressed between the tank shell and the floating roof rim effect high efficieny sealing performance.

ATS-FS5 Foam Seal is designed for product mounted or vapor mounted type.

| [rtbs name=”graver-foam-seal”] |

|

|---|

: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

34

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4331

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4368

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4379

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

66

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

34

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4331

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4368

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4379

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

66

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

34

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4331

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4368

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4379

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

66

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

34

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4331

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4368

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/themegum_functions.php on line

4379

Deprecated: Function create_function() is deprecated in

/var/www/vhosts/atecotank.com/httpdocs/wp-content/themes/petro/lib/widgets.php on line

66